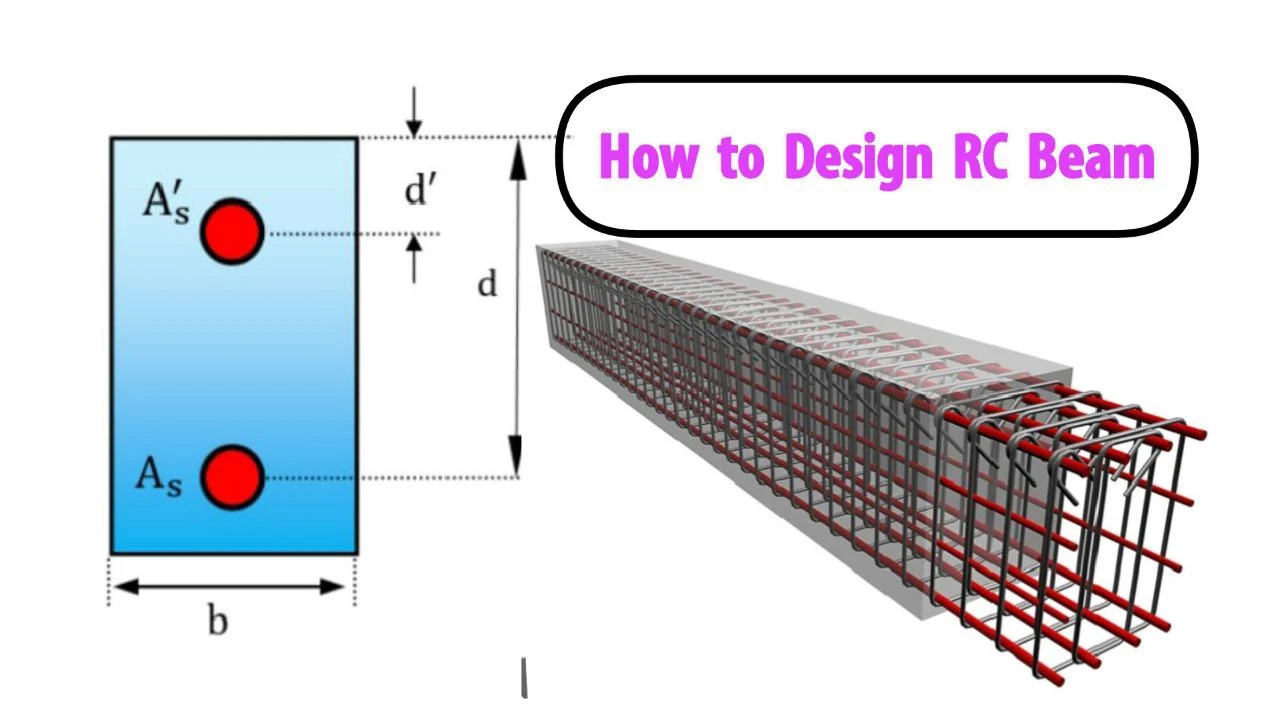

Reinforced Concrete (RC) beams are a core component of modern structures, providing the necessary strength to support loads and transfer them safely to the columns and foundations. Whether you're a civil engineering student, a young professional, or a construction enthusiast, understanding how to design an RC beam is essential.

|

| RC Beam |

In this post, we’ll walk you through the step-by-step process of RC beam design as per standard engineering practice (aligned with codes like IS456), including formulas, tips, and important checks to ensure safety and efficiency.

What is an RC Beam?

An RC beam is a horizontal structural element designed to carry transverse loads. It’s made of concrete and reinforced with steel rebars to resist tensile stresses that concrete alone cannot withstand.

The below are the step to design RC Beam:

Step 1: Understand the Requirements

Step 2: Preliminary Beam Size

Step 3: Load Calculation

Step 4: Calculate Effective Depth (d)

Step 5: Moment of Resistance (Mu,lim)

Step 6: Calculate Area of Steel (Ast)

Step 7: Select Number and Size of Bars

Step 8: Check Shear Strength

Step 9: Check Deflection Control

Step 10: Check Development Length (Ld)

Step 11: Detailing and Drawing.

Calculations Process Details of RC Beam

Step 1: Understand the Requirements

Before any calculations, gather the following data:

- Span length of the beam

- Type of beam: Simply supported, cantilever, or continuous

- Loads acting: Dead load, live load, point load, distributed load

- Material properties:

- Grade of concrete (e.g., M20, M25)

- Grade of steel (e.g., Fe415, Fe500)

- Support conditions

- Applicable design code (e.g., IS 456:2000)

Step 2: Preliminary Beam Size

Use thumb rules or experience to estimate the initial dimensions. Common thumb rules for depth:

- Simply supported beam: Depth (D) = span/15 to span/20

- Continuous beam: Depth = span/20 to span/25

- Cantilever beam: Depth = span/10

Assume an initial width b = D/1.5 to D/2. Adjust as needed later.

Example: For a 4-meter span (4000 mm):

- Depth = 4000 / 15 = approx. 270 mm

- Width = 270 / 1.5 = 180 mm

Try 230 mm width x 300 mm depth as a starting section (including cover).

Step 3: Load Calculation

You have to determine the total factored load on the beam:

1. Dead Load (DL):

Includes self-weight of beam and permanent loads.

Self-weight = Density of concrete × Cross-sectional area

= 25 kN/m³ × (b × D) in m²

2. Live Load (LL):

Varies by use (residential, commercial). Use code-specified values.

3. Factored Load (Mu):

Use Load Factor (generally 1.5):

Mu = 1.5 × (DL + LL)

If it's a uniformly distributed load (UDL), moment is:

Mu = (w × l²) / 8 (for simply supported).

Step 4: Calculate Effective Depth (d)

Effective depth = Total depth – cover – ½ diameter of main bar

Assume cover = 25 mm, bar = 16 mm

So, d = 300 – 25 – 8 = 267 mm.

Step 5: Moment of Resistance (Mu,lim)

Check the moment-carrying capacity of the section. For a singly reinforced beam (under-reinforced):

Mu,lim = 0.138 × fck × b × d²

Where:

fck = Characteristic strength of concrete (e.g., 20 MPa for M20)

b = width of beam

d = effective depth

If the factored moment Mu < Mu,lim, singly reinforced design is OK.

If Mu > Mu,lim, doubly reinforced design is needed.

Step 6: Calculate Area of Steel (Ast)

To resist Mu:

Ast = Mu / (0.87 × fy × jd)

Where:

Mu = factored bending moment

fy = yield strength of steel (e.g., 415 MPa)

jd = lever arm ≈ 0.9d (for approximate)

Always check minimum reinforcement:

Ast(min) = 0.85 × b × d / fy

Use higher of calculated or minimum.

Step 7: Select Number and Size of Bars

Choose bar diameter (e.g., 12mm, 16mm) and calculate number of bars needed:

Area of 1 bar = (π/4) × d²

Divide total Ast by area of 1 bar to get the number of bars.

Round up to the next whole number.

Example:

Required Ast = 600 mm²

Using 16 mm bars: area = 201 mm²

600/201 ≈ 3 bars → use 3 or 4 bars of 16 mm

Step 8: Check Shear Strength

Shear force (Vu) = Total shear load at support

Nominal shear stress, τv = Vu / (b × d)

Find the design shear strength of concrete (τc) from code tables using fck and percentage tension steel.

If τv < τc: No shear reinforcement needed (minimum stirrups only).

If τv > τc: Provide stirrups (shear reinforcement)

Calculate spacing of stirrups:

Sv = (0.87 × fy × Asv × d) / Vu

Where Asv = area of 2-legged stirrups

Use standard stirrup bar (e.g., 8 mm)

Step 9: Check Deflection Control

IS 456 provide span/depth ratios.

Basic span/depth ratio (for simply supported): 20

Apply modification factors (for % steel, tension, compression, etc.)

If actual span/depth < allowable, deflection is OK.

Step 10: Check Development Length (Ld)

Steel bars must be embedded properly to transfer stress:

Ld = (φ × fy) / (4 × τbd)

Where:

φ = bar diameter

τbd = bond stress (from code)

Ensure anchorage length provided ≥ Ld

Step 11: Detailing and Drawing

Prepare detailed drawings showing:

Step 12: Final Design Checklist

You have to check all in below:

- Section size adequate?

- Bending moment satisfied?

- Shear strength adequate?

- Bar spacing OK?

- Development length provided?

- Deflection within limits?

- Detailing complete?

Tips for Efficient RC Beam Design

Common Mistakes to Avoid

- Ignoring shear design

- Inadequate anchorage

- Not checking serviceability (deflection, cracking)

- Improper detailing or bar placement

- Using thumb rules blindly without checking

Conclusion

Designing an RC beam may seem complex, but when broken down into steps, it's a logical and systematic process. With the right understanding of loads, material strengths, structural behavior, and code requirements, you can confidently design safe and efficient RC beams.

This guide gives you a strong foundation to understand the principles behind the design and ensures you're aligned with industry standards.

Do You Want More Engineering Guides?

If you found this post useful, share it, leave a comment, and subscribe for more civil engineering tutorials, tools, and career tips. Don't forget to check out our other articles on slab design, column design, and structural analysis.